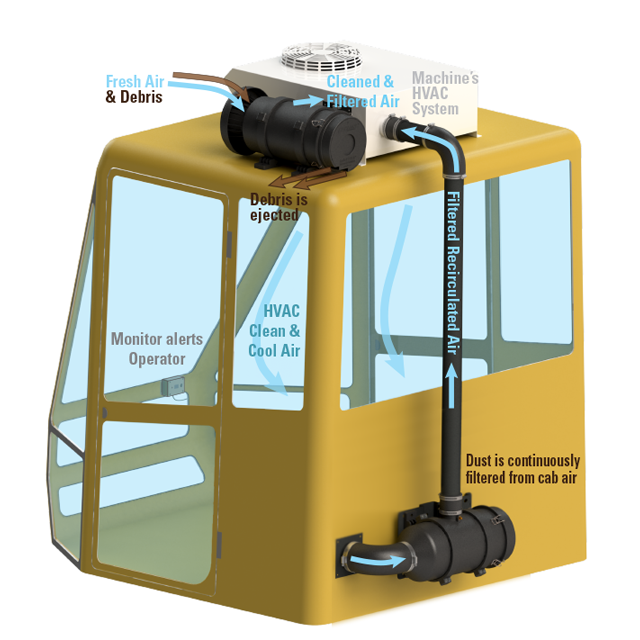

How Complete Cab Air Quality System Works:

Sy-Klone Cab Air Quality Systems

A complete system is comprised of three main parts:

How Complete Cab Air Quality System Works:

Why use a Sy-Klone RESPA Air Quality System?

Where can you use the RESPA Air Quality Systems?

United Safety Capability

Protect Workers’ Air Quality. Reduce Occupational Exposure to Dust and CO2

AS/NZS ISO 23875 is an international standard that creates a consistent approach to designing, testing, operating,and maintaining operator enclosures with respect to air quality.

What is AS/NZS ISO 23875?

Published in February 2021 and updated in 2022, ISO 23875 is a new international standard that unifies the design, testing, operation, and maintenance of air quality control systems for heavy machinery cabs and other operator enclosures, particularly in the mining industry. Adherence to the requirements and testing methods set out in the standard supports the safety of machine users, improves productivity, promotes operator alertness, and enables companies to reach exposure reduction goals.

Benefits of Implementing AS/NZS ISO 23875

• Reduced exposure to respirable particulate

• Reduced exposure to CO2

• Improved operator safety, comfort, and moral–supporting exposure reduction goals, health and safety efforts, and recruitment/retention

• Improved machine uptime and lower operating costs through meeting defined maintenance intervals

AS/NZS ISO 23875 Requirements